Your questions answered

What size generator to run my welder?

I wish the answer was a simple yes, hang on it is a yes. If you read the following article you will see what you need.

What size Generator Do I Need to Run My Inverter Welder/Welder?

We answer all these questions and more! Here’s what we cover in this article;

1. Generator power vs Grid power

2. Why is generator power potentially harmful to your welder?

3. Why are inverter welders vulnerable?

4. Input voltage protection

5. Guidelines for generator use with inverter welders

6. Can I use a small generator to run my welder?

7. Tips for purchasing a suitable generator

Generator Power V Mains

Compared to mains power, generator power can be sometimes be called dirty and has the potential to damage sensitive electronic components inside inverter welding machines. This is especially the case with smaller generator sets that are often chosen for operating power tools and welders, due to their portability and affordability.

Generator power offers many advantages to people wanting to run their inverter welding machines in the field or on-site where it is impossible or difficult to access mains power.

So, it’s no surprise that one of the first questions people ask before they consider purchasing a generator to run their inverter welder is: “is it safe to run off a generator?”. The truthful answer is not always a “yes”. Sure, plug virtually any inverter welder into a generator and it will likely operate to some level. But not all generators have the control required to avoid ‘dirty’ or unpredictable power supply in the long term.

Why is generator supplied power potentially harmful to inverter welders?

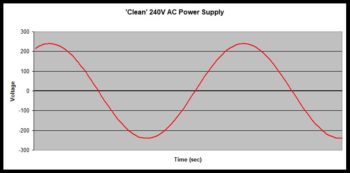

AC (mains) power supply follows a pattern called a sine wave. When it comes to running equipment with sensitive electronics (like inverter machines and computers) power supply with a perfectly clean sine wave is the safest, however in reality this is almost impossible to achieve.

A perfectly ‘clean’ 240V single phase AC sine wave would look something like this:

Mains power is (usually) relatively close to perfect sine power and therefore it rarely poses any problems.

On the other hand, power supply from a portable generator can be, by comparison, ‘dirty’. The peaks, troughs and cycle frequency will not be consistent even though the average output power may still read 240V on a simple measuring device like a multimeter. Generator power can also be characterised by voltage ‘surges’ (a rise in voltage) and voltage ‘spikes’ (very sudden peaks of excessive voltage).

In a generator, voltage surges and spikes can occur due to a number of reasons, including:

a. Generator Quality: All portable generators typically produce inconsistent power when compared to perfect sine wave power. This degree of variation from perfect sine wave power is measured as a percentage called ‘Total Harmonic Distortion’ or THD. An acceptable THD rating in a portable generator is generally considered to be 6% or less. In recent years the market has faced a lot of imports of cheap, poor quality generators with unacceptably high THD ratings (over 6%). While these cheaper generators may run basic power tools without a problem, they are not suitable for running inverter-based machines because the voltage is likely to fluctuate and spike at an unacceptably severe level.

b. Start up and Shut down: When starting and stopping a generator the engine is obviously not running smoothly and at a constant speed and therefore the output of the generator is very likely to fluctuate with engine speed. Don’t leave your welder plugged in and on before starting or stopping or you are looking for trouble. Get in the habit of turning it on and off at the switch.

c. Fuel supply interruption: Like start up and shut down, if the generator runs out of fuel, or if there is a ‘hiccup’ in the fuel supply, the engine will typically speed up and slow down very spasmodically, again causing power fluctuations.

d. Loading vs. Generator size: A generator that is under-sized &/or over-loaded will work very hard to try and maintain sufficient current supply. Then when the load is removed (eg when welding stops), the engine will typically over-rev until the governor returns the engine to idle speed. This over-revving the generator will very likely increase the voltage output, sometimes to a dangerous level.

e. Additional loads: The use of other devices (eg; grinder, cut-off saw, etc) on the same generator and at the same time as the welding machine can cause overloading, and therefore cause power fluctuations, if the generator size is not sufficient.

f. Lack of maintenance: A poorly maintained generator will behave in the same way that a poor-quality generator does.

Why are inverter welders vulnerable?

In order to significantly reduce the size of the transformer and achieve the many advantages that the inverter gives us (reduced size/weight, etc), the input power must be ‘treated’ before it enters the transformer – in other words instead of immediately passing through the transformer, it first passes through sensitive electronic components.

The main components of concern are capacitors. Capacitors are devices which constantly charge and discharge voltages. In an inverter welder, the capacitors will charge at approximately 1.4 times the standard input voltage. So in the case of 240V power supply they will charge at about 335V. The same will occur in the case of a voltage surge or spike. So for a 280V surge, they would charge at about 395V which is a voltage increase of 155V. It is this significant fluctuation in working voltage that can damage or destroy electronic components in an inverter welding machine.

Superior technology from Powerlite!

At Powerlite, we recognise that many people (especially in rural, construction and maintenance industries) have the need to run their welder off a generator.

Powerlite Made in Australia generators are specifically developed with inverter welder use in mind and have a high level of protection against voltage fluctuations. For peace of mind, the Powerlite warranty includes/covers the use of inverter welding machines with a Powerlite generator (providing that the operator complies with the guidelines included in the instruction manual).

The following features have been incorporated into Powerlite welder-friendly generators to ensure optimum protection from power supply fluctuations:

• Automatic Voltage Regulator: This device monitors the output voltage of the machine and if the voltage rises above (or below) a certain level the machine automatically adjusts the voltage supply to the outlets. These high and low parameters on the Powerlite generators are set at 240V +/- 15% (200V – 280V).

• Voltage Surge Protector: Powerlite Welder Friendly Generators incorporate high performance voltage surge protection which protect the machines from higher input voltage fluctuations and reduce the risk of damage to the capacitor and other components used in the inverter welding machines.

Guidelines for running inverter welders on a generator.

By following these guidelines, the operator will minimise the risk of damaging voltage spikes and help the welding machine to perform to its full capacity.

Generator Size:

Determining the exact generator size required to safely run a welding machine is not always a straightforward process. Some of the factors to be considered are: the current draw ratings of the welder, the rated output of the generator and whether this is a genuine rating (unfortunately some generators are over-rated), whether the generator will or will not be used to run other power equipment at the same time, etc.

For recommended generator sizes to run specific welding machines, refer to the instruction manual of the welder you wish to run.

Following is a Suggested minimum generator size ‘rule of thumb’ guide*;

Inverter

Welder

Max. Output Suggested

“Minimum”

Generator Size** Suggested

“Ideal”

Generator Size***

Up to 160A 7kva 8+kva

180–200A 8kva 10+kva

250A 13kva 15+kva

The do’s and don’ts for running an inverter welder on a generator?

a. Start-up & Shutdown: Always disconnect the welder’s power lead from the generator before starting or stopping the engine on the generator.

b. Fuel Supply: Always ensure that the generator engine has a safe supply of fuel and that the fuel line is in good condition. The engine should not be allowed to run out of fuel while the welder is connected to the generator.

c. Maintenance: Always keep the generator in good condition. Do not use a generator that is in need of service or replacement.

d. Power Extension Leads: Do not use power leads that are of poor quality or in need of repair or replacement. Always use heavy duty leads – see table below.

Suggested Guide for cable size of extension leads used with Inverter Welding Machines*:

Welding Machine

Max. Output Power Supply Suggested Minimum

Cable Size*

Up to 200A 240V 10A/15A Lengths up to 10m: 2.0mm2

Lengths over 10m: 2.5mm2

250A 240V 15A 2.5mm2

240V 20/25/32A 4.0mm2

Can I use a small generator to run my welder?

As shown in the table above, the recommended minimum generator size is not less than 7kva (for up to 160A welders). We often get asked questions like “why can’t I use my 5kva generator to run this welder?”.

We also sometimes see other welding machine suppliers suggesting that their machines can be powered by generators as small as 4-5 kva.

Sure, the welder might actually operate to some level, but here’s why using smaller under-sized generators is NOT a good idea;

a. As explained above, the generator will have to work much harder and this will greatly increase the likelihood of severe power spikes that could damage the welder or cause it to frequently shut down.

b. The output from the welder will be significantly reduced, possibly to the point where the machine is of little use… or becomes very frustrating to the operator.

c. Often the generator will be used at some point to operate other equipment (eg power tools) at the same time and this will further compound the above problems.

Although a larger generator will cost more initially, a correctly sized (or over-sized) generator will allow you to get the job done right the first time… and greatly reduce the risk of costly damage to your welder. And who ever regrets having ‘too much’ performance?

https://powerlite.com.au/pure-sine-wave-generator-the-truth/